Wire Rope Slings BS 1290

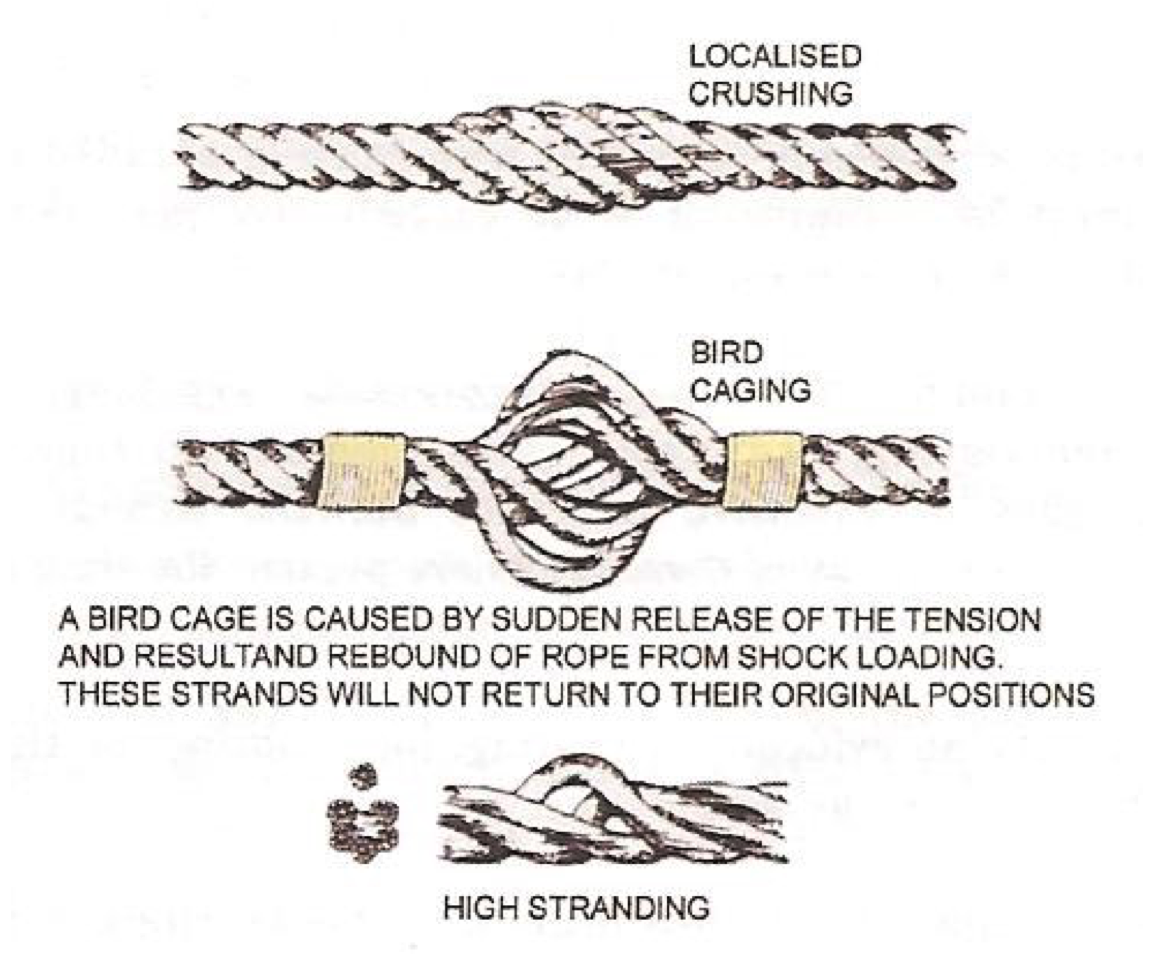

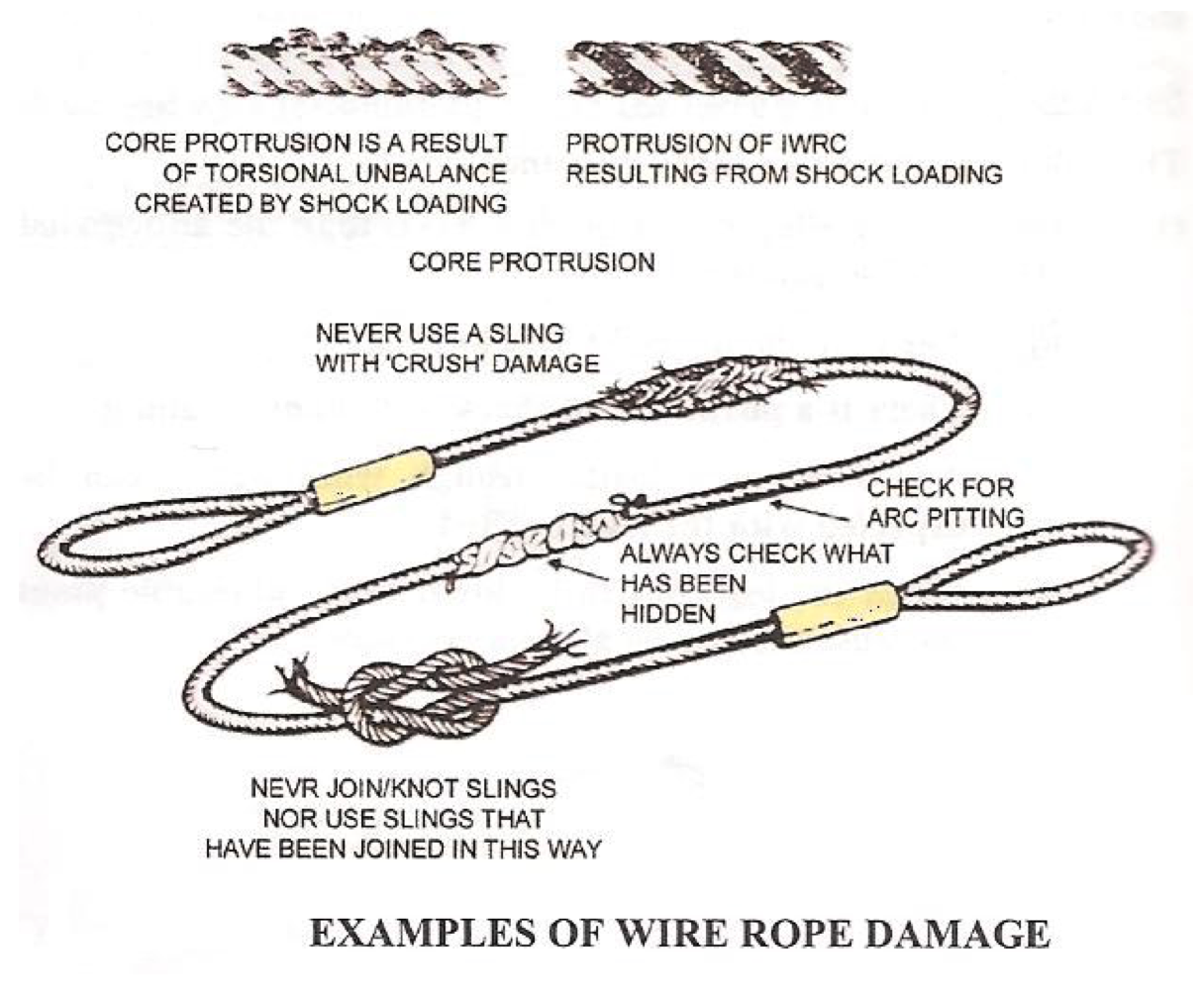

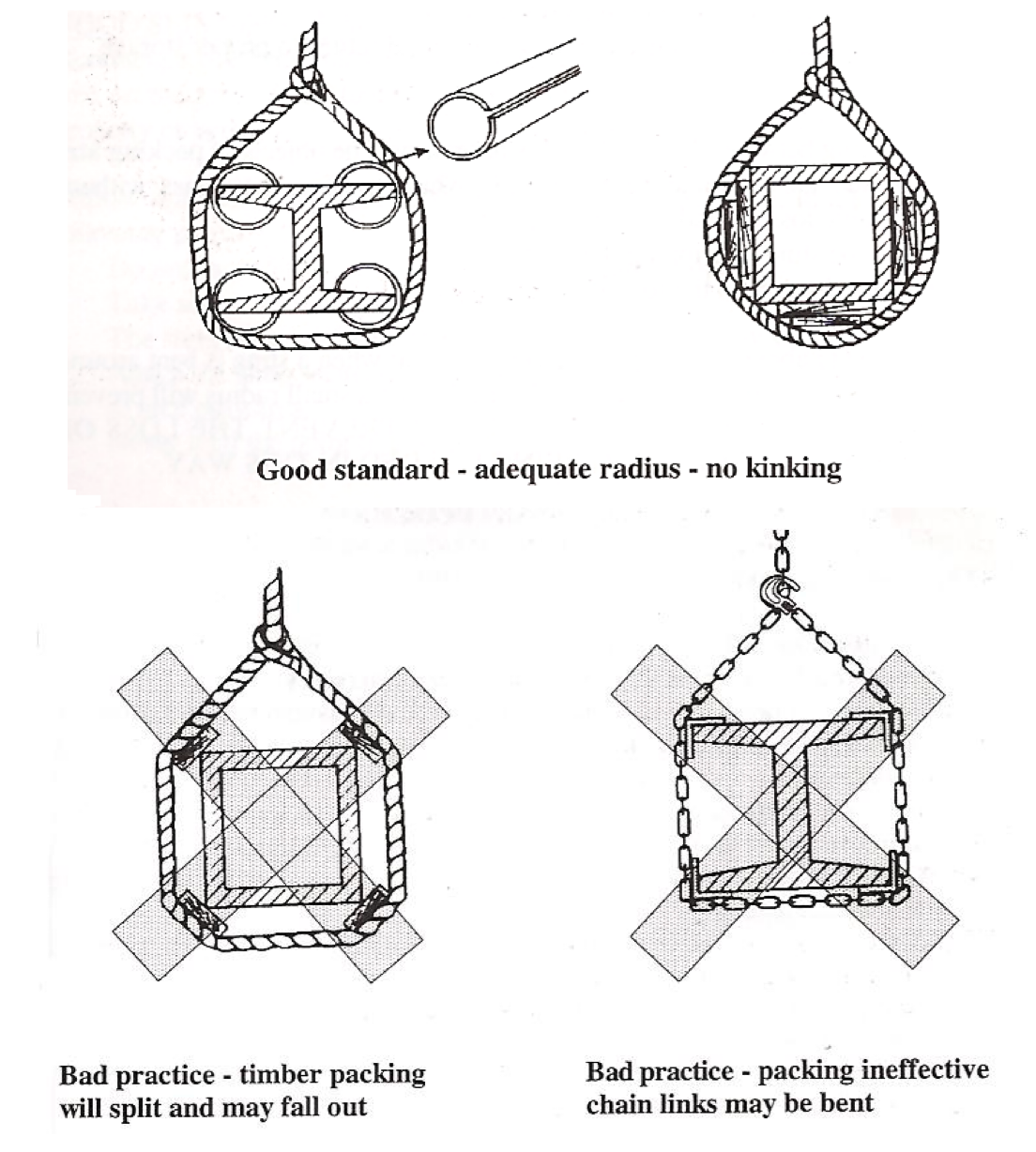

Wire rope slings require care in handling and attention in use. Steps should be taken to protect them from wear, abrasion, crushing and kinking.

Before Use Inspection

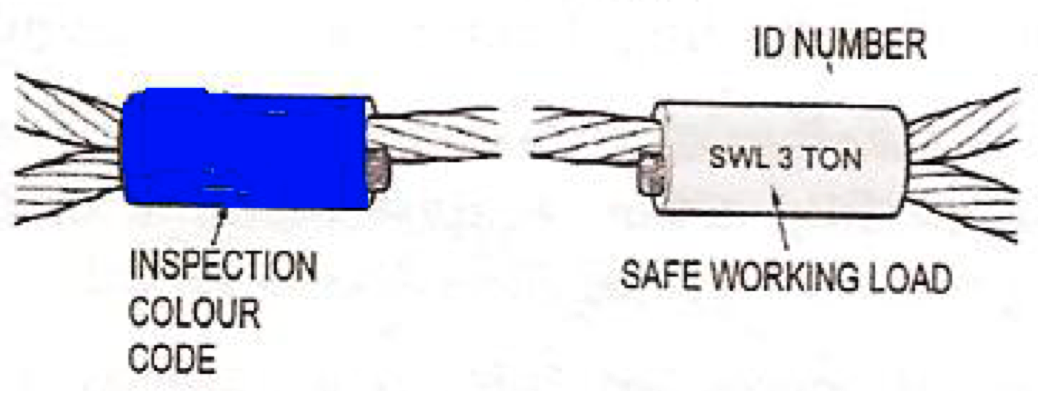

A pre use inspection by the user must be done before the sling(s) are used. Occasionally wire failures may be found early in the life of any wire rope and in most cases there is no requirement to destroy the sling provided the wire failures are well spaced intervals.

A sling must be scrapped if – there are 3 or more broken wires in any 1 lay. The rope lay is the length along a rope in which on strand makes a complete revolution round the rope, the wire must fail checks if, in any length of 10 diameters the total number of broken wires exceed 5 percent of the total number of wires, also the sling must be scrapped if there are any broken wires where the sling enters the ferrule.

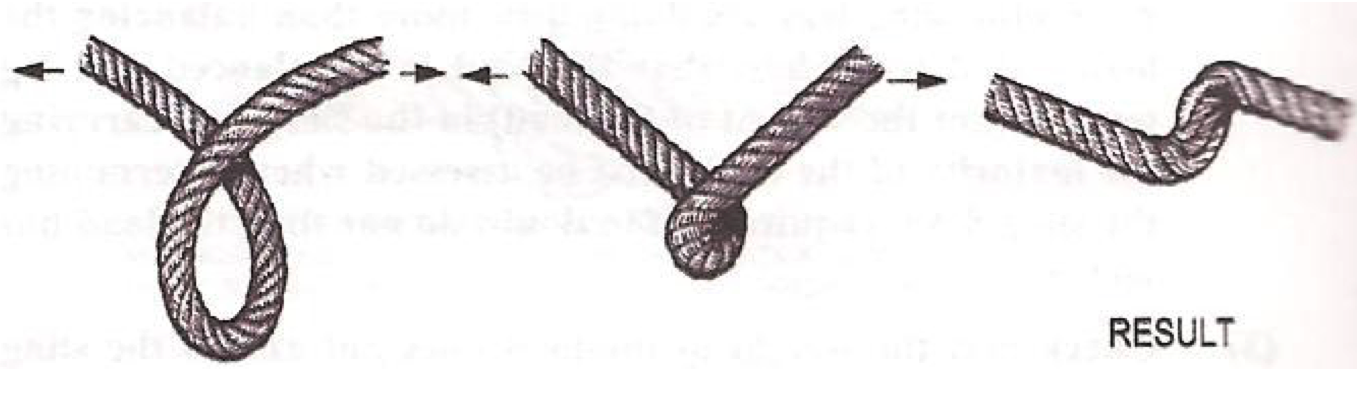

Take care never to kink a sling, a sling with a kink in it will have a dramatic effect on the SWL and it should be removed from service. Kinks are normally formed in two ways

- Bad slinging practices – attaching the sling over sharp or acute angles or wrapping around small diameters.

- By pulling on a loop formed in the sling – if pulled instead of untwisting a kink will form.

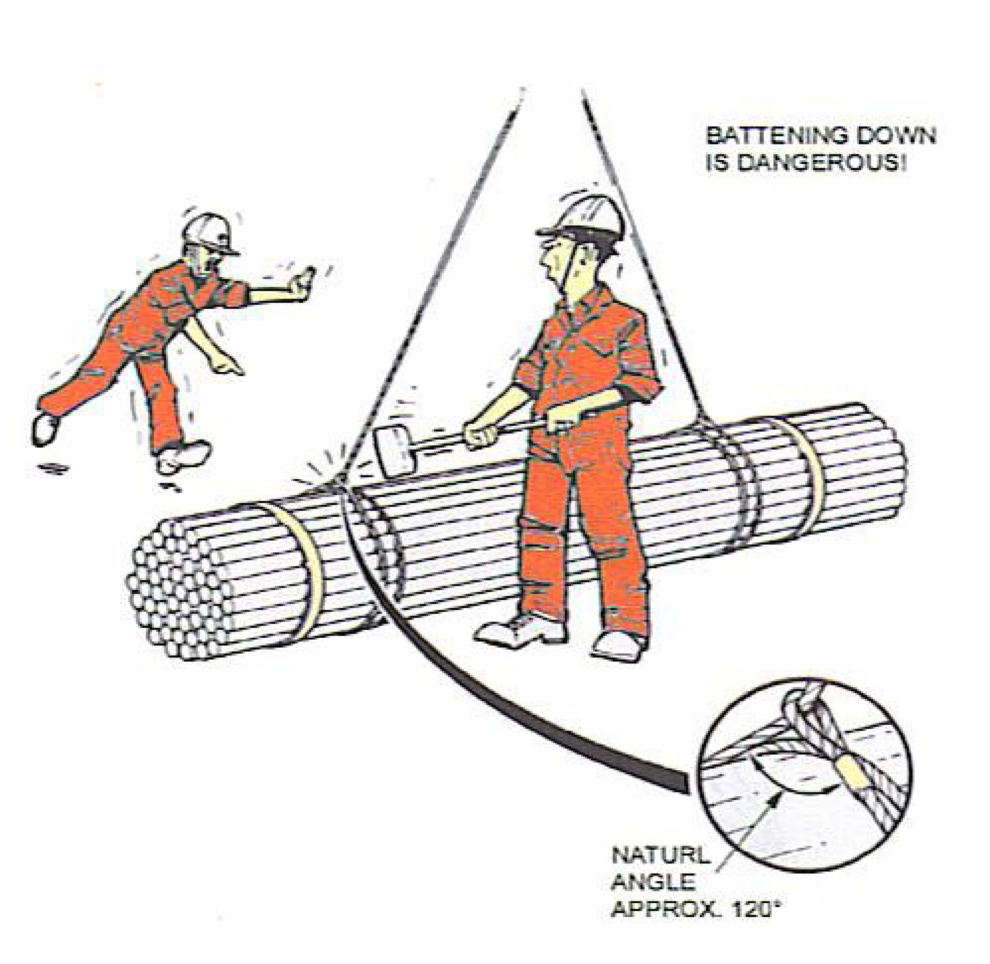

It is important that when we sling loads that we allow the slings to form a natural angle at the choke. We do not attempt to batten this down, if we try and knock the slings down all that we are doing is applying a greater angle at the choke resulting in decreasing the sling SWL and also it could result in damage to the sling.

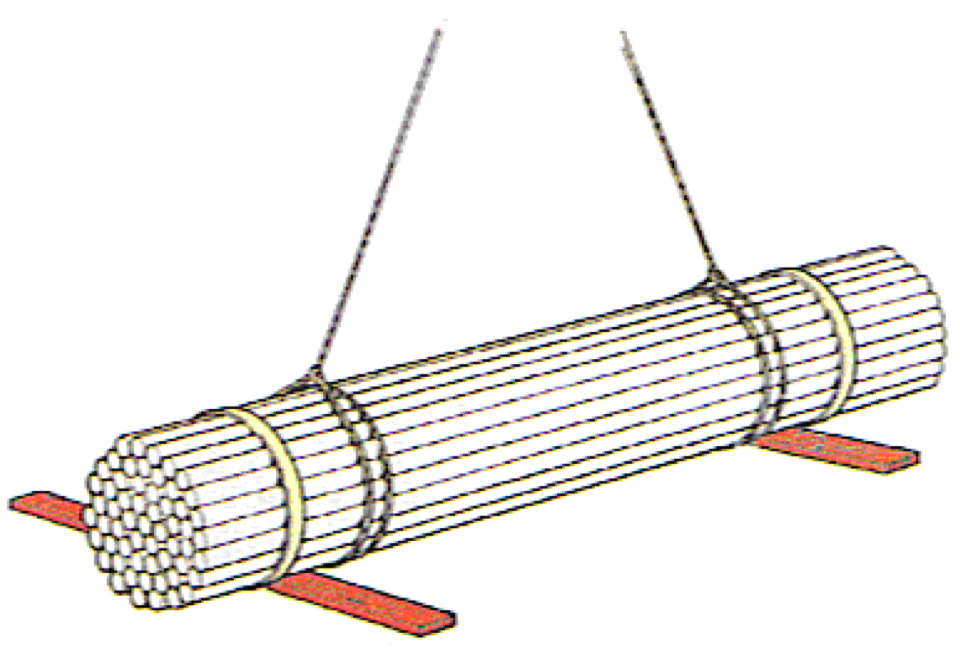

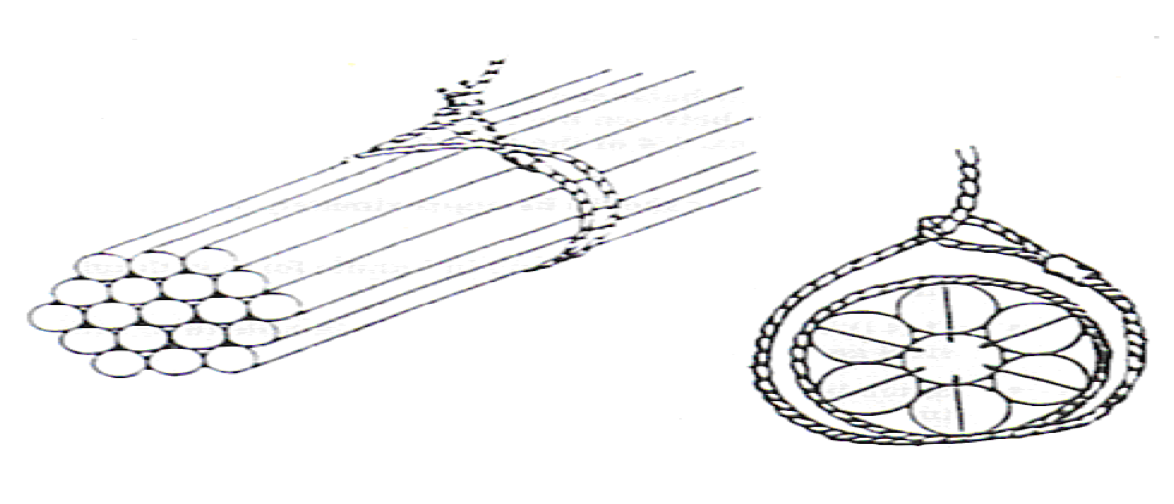

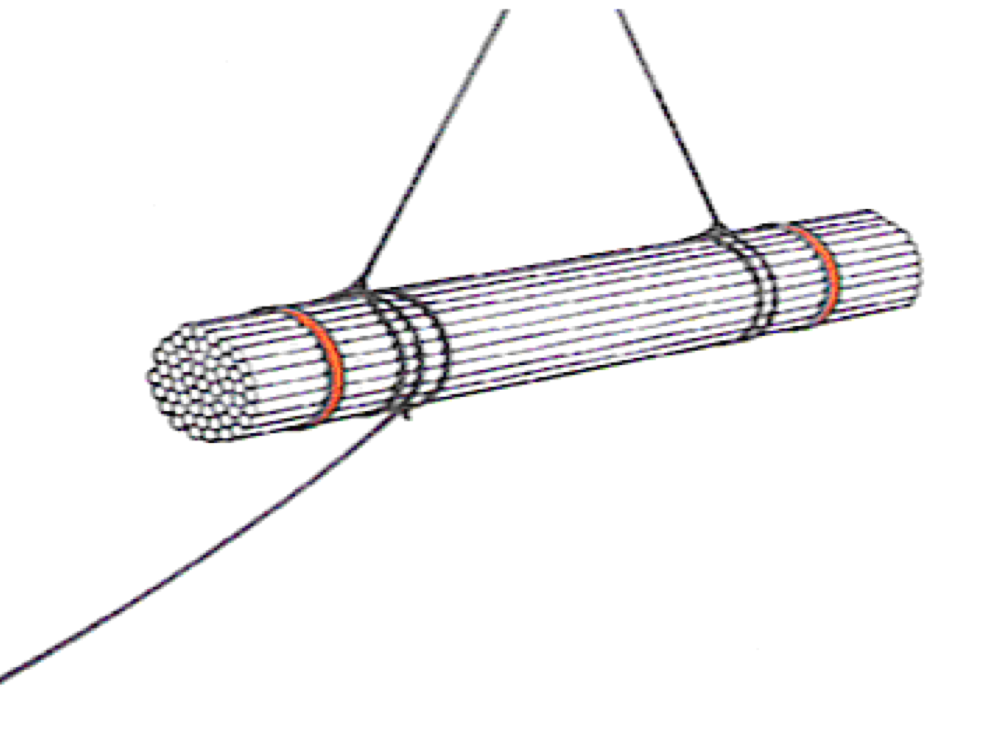

Double wrapping of the slings on tubulars helps to compress the load by applying 360 degrees pressure and gripes the pipes in a safe bundle.

Using tag lines

Taglines should be attached to the load and not the slings, just in case the slings are pulled from the load.

Loads should always be landed on pieces of timber or similar to allow the removal of the slings without damaging them.